In a world where uptime and agility shape event schedules and industrial workflows, a distribution Socket Box can evolve from a passive junction into an active asset when paired with smarter monitoring. Imagine a cabinet that senses contact heating, flags loosening screws, and signals a service crew before guests notice a flicker. These ideas are moving from research labs into field trials, and they change how planners think about reliability on site.

Artificial intelligence plays a growing role in that shift. By feeding sensor streams into models that spot subtle anomalies, systems can predict when a connector or a busbar will need attention, so maintenance becomes scheduled instead of reactive. This approach reduces emergency call outs and helps teams plan spare parts, manpower and access windows more intelligently. Pilot projects and industry reviews show clear interest in AI driven maintenance across distribution equipment and panel level assets.

The underlying toolkit combines affordable sensors, edge processors and networked analytics. Temperature and vibration transducers, along with simple current monitors, feed short term trending that reveals slow changes. Edge nodes summarize data and send only meaningful events to central systems, keeping bandwidth and privacy needs manageable while letting local crews receive actionable alerts on mobile devices. Vendors and integrators are packaging these elements so that retrofits to existing enclosures are feasible without replacing entire installations.

Beyond prediction, the idea of circuits that can reconfigure themselves is gaining traction in grid scale research and could inspire next generation distribution points. Self healing strategies use automated sectionalizing to isolate a fault, shift loads and restore service to unaffected areas while crews address the root cause. Applied at a smaller scale within a field enclosure, similar logic could isolate a troubled branch and preserve power to other channels, shortening perceived downtime for end users. Research institutions and industry groups are actively exploring these capabilities.

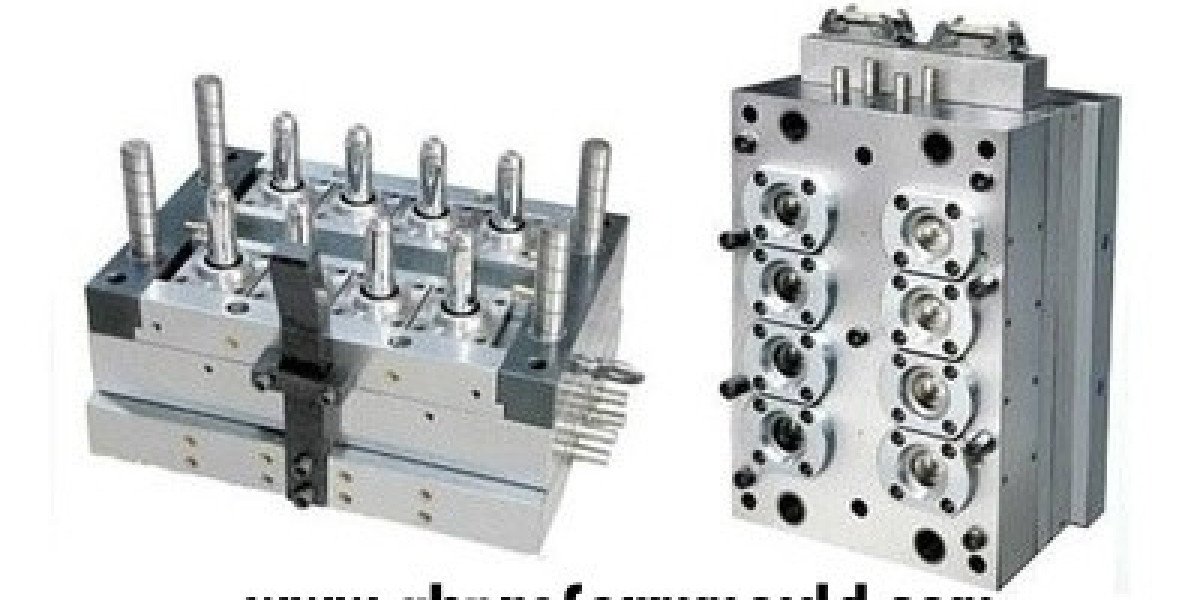

Practical deployment blends smart functions with rugged design. A combined socket box that includes protective covers, clear labeling and modular inserts makes it easier to add sensors and swap failing modules in minutes. When hardware supports neat cable entry and easy access to terminals, field checks become faster and sensor wiring stays tidy. That reduces the friction of adopting predictive maintenance and makes it realistic for event teams and facility managers who cannot afford long outages. Manufacturer resources emphasize modularity and accessibility as enablers of smarter upkeep.

Security and operational policies matter alongside technology choices. Data flows must be managed so alerts go to the right people and so remote control functions require robust authorization. Routine drills that exercise automated isolation and verify alerting reduce false confidence and make sure the human side of a response is practiced. When planners combine well defined escalation paths with instrumented hardware, the result is measured resilience rather than just clever gadgets.

Cost planning tends to focus on avoided downtime and reduced emergency labor. Predictive systems let teams forecast parts consumption and plan interventions during quiet hours, which lowers the operational disturbance that often accompanies unplanned repairs. For site owners the financial case includes smoother programming and the reduced reputational risk of a visible failure during a public activity.

If you are curious about product platforms that support modular inserts and clear access for sensors and service, supplier material describes combined enclosures designed for field use and retrofit. Those product notes highlight design choices that ease the integration of monitoring and that help technicians perform quick swaps in the field. To view product options and accessory guidance that support smarter maintenance workflows visit www.nante.com where configuration notes and practical details are available to help match hardware to evolving site needs.